Sandblasting Glass

A sandblaster for glass etching is a great tool to add character to glassware, windows, and anything glass in fact. Later we will focus on the actual tools. For now, the actual process, if not done right, can lead to frustrating results. In this article we briefly discuss the concepts associated with glass engraving. The first point we should bring up is the difference between engraving and etching. After that we’ll focus a bit on the actual process of sandblast glass etching and show off some samples of sandblasted glass.

Glass Etching or How to Engrave Glass?

Well, which is it? The debate goes on about which is which. Our perspective is that sandblasted glass is known as engraving. A chemical process is most commonly given the name engraving. We do not have expertise on chemical engraving, but we do with sand blasting glass. Without getting into a debate on which is correct, in our article we will use both terms interchangeably in this article.

Sandblasted Glass

Like anything else, you have to have something in mind before going down the path of sandblast etching glass. Whether you are going to be doing this as a business or just a hobby, sand etching glass can be overwhelming. Glass is a delicate material to work with, but with proper planning and care you too can successfully obtain a great etched glass texture on almost any piece of glass.

A wine glass after we sandblasted it.

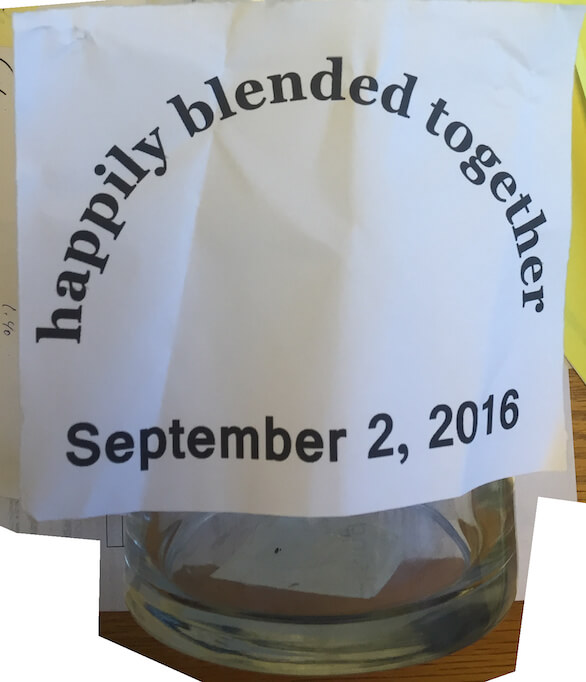

The paper we used to mask a vase shown later in the article.

Etched Glass Texture

The texture produced on glass by a sandblaster is often called frosted glass. As you guessed, it appears similar to a windshield on a frosty morning. In sandblast glass etching, however, the effect is produced by the abrasive delivered to the glass surface.

Sandblasted Glass – The Glass

Many choose drinking glasses of some kind to sandblast, others may choose another form of glassware. We have examples in our lab of vases too. No matter what you choose, it should be all about you. If you are focusing on glass etching for commercial purposes, of course you’ll want to understand your market.

Sandblasting Glass – The Mask also known as a resist

After selecting your glassware, you’ll need to consider what you’ll be sandblasting onto the item. Again, whether for personal or commercial you pick what goes on the glass. But wait, how can you get a cool design, phrase or logo onto a piece of glass? We are quite certain there are many talented people out there who can free hand sandblasted etched glass. For the rest of us, we need some help. For that purpose, many people turn to a mask of some kind.

How to Etch Glass – Masking Options & Techniques

Masking can be done in a variety of ways. Painters tape, paper, and UV light sensitive adhesive material. The latter is a very efficient and reliable way to transfer almost any image or text onto glass to be blasted. With the UV material, you first print your image onto paper. Then, you lay it on top of a special material sensitive to UV light. Then, you place the UV material, paper into a UV light. After a few minutes, the UV light hardens the area to be sandblasted but leaves the remainder of the special UV material soft. This is so that when you begin sandblasting the glass, the hardened are of the material is blasted away and your abrasive material makes direct contact with the glass. Thus, it engraves the glass! More on this to come.

Sandblaster for Glass Etching

As you saw above, glass etching/engraving begins with an idea. We are a manufacturer of sandblasting equipment. Our product catalog includes sandblasters and abrasive media that can be used for glasswork. We are not a source for masking material nor are we a glass engraving company. Being a family business though, we sometimes get requests we honor with pride. Shown at the left are a few examples of a vase that we produced with one of our blast cabinets. The bride to be approached us with a request for an engraved vase that we proudly honored. You saw the paper concept above. To the left you see the finished results. The bride and groom both had existing families and together the entire family poured sand into the vase symbolizing the coming together of them all into one.

Sandblaster Options for Etching Glass

When it comes to a sandblast cabinet there are many options out there. Too many in fact for us to list. We have several articles about direct pressure vs. gravity fed in our site. In brief, pressure in most circumstances performs faster work than siphon. For your unique projects or plans, contact us for specifics. Overall, selecting a sandblaster for glass etching involves size of the project you are blasting.

Sandblast Cabinet Sizes

If you are going to be doing glassware or small pieces, a smaller cabinet is likely going to fit your project and budget. Larger objects like glass windows or glass door panels will require a larger cabinet. In some cases you may need a customized cabinet. Don’t worry, the word customized with us does not mean more expensive. It simply means the cabinet is suited to how you will be blasting. For instance, we can provide a “pass through” cabinet for customers who will be blasting large panes of glass. A pass through cabinet allows the glass to sit on rollers and into the cabinet to be blasted. Specially designed seals keep the abrasive media inside the cabinet where it belongs.

Benchtop Sandblasters

Small sandblasters for glass etching. Our E100 series offers three variations. Most popular for glass etching and engraving are the E100P and E100 LTC. They offer powerful blast streams in a narrow blast stream. Ideal for precision work like sandblasted glass.

Abrasives for Glass Etching

Another debatable position when sandblasting glass is what abrasives for glass etching are best. A sharp abrasive is important because it actually can “cut” into the surface of the glass and remove material, thus producing frosted glass. In order to do this, the abrasive must be sharp and stay sharp for a prolonged period. Overusing an abrasive can produce a fine dust. This dust can make it difficult to see your work. And with some abrasives, static electricity is produced which can cause the dust to collect on your glassware. Again, this makes it difficult to efficiently work on your glassware project.

Abrasive Safety

Make not mistake about sandblasting. Despite the name, we have never and will never recommend using sand in a sandblaster. Contrary to the name, the sand in sandblasting may contain silica. This can cause a condition in the human lung caused silicosis. There are safer options for etching glass. However, no media is 100% safe, so always read, follow, and obey safety instructions manuals and best practices. We want you to be safe but your safety is ultimately your own responsibility!

Aluminum Oxide

Aluminum oxide is a popular abrasive for glass etching. It is sharp and can be reused several times before needing to be replaced. Specifically, we offer brown aluminum oxide when sandblasting glass. White aluminum oxide is actually slightly harder than brown, but it is more fragile too. Without an in-depth article on the differences, all glassware shown above was blasted with brown aluminum oxide. Let us know if you have specific questions for your project and we can discuss them directly with you.

Silicon Carbide

Another popular blasting abrasive when sandblasting glass is silicon carbide. As with aluminum oxide, silicon carbide is very sharp and very hard. It’s extremely durable and can be reused many times before requiring replacement. Therefore, it’s an excellent choice for sandblasted glass. Silicon carbide, upon impacting the surface, tends to break into smaller sharp pieces. Aluminum oxide, in contrast, will break into small pieces and mostly dust over time. Thus, silicon carbide can cut faster and last longer than aluminum oxide – in most situations.